What Are You Looking For?

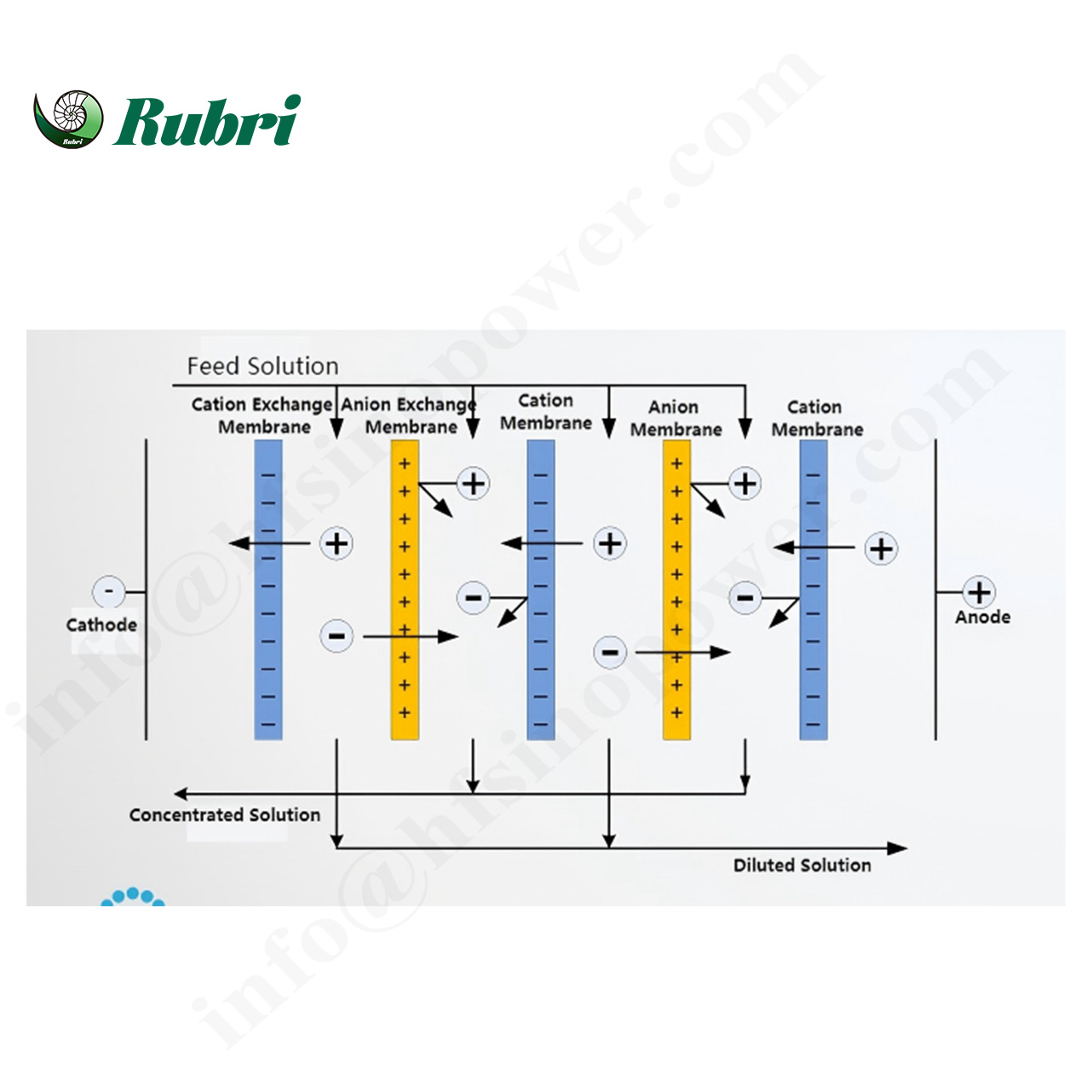

Core Principle of Electrodialysis

The core of electrodialysis technology lies in the combination of electric field and selective membrane technology, with the specific principle divided into two parts:

1. Driving effect of DC electric field

Under the action of a DC electric field, anions and cations in the solution move directionally: cations migrate toward the negative electrode, while anions migrate toward the positive electrode.

2. Selective sieving effect of ion exchange membranes

Two types of ion exchange membranes are used in the system to achieve ion separation:

Cation exchange membrane: Only allows cations (e.g., Na+, Ca2+, Mg2+) to pass through, while blocking anions.

Anion exchange membrane: Only allows anions (e.g., Cl-, SO42-) to pass through, while blocking cations.

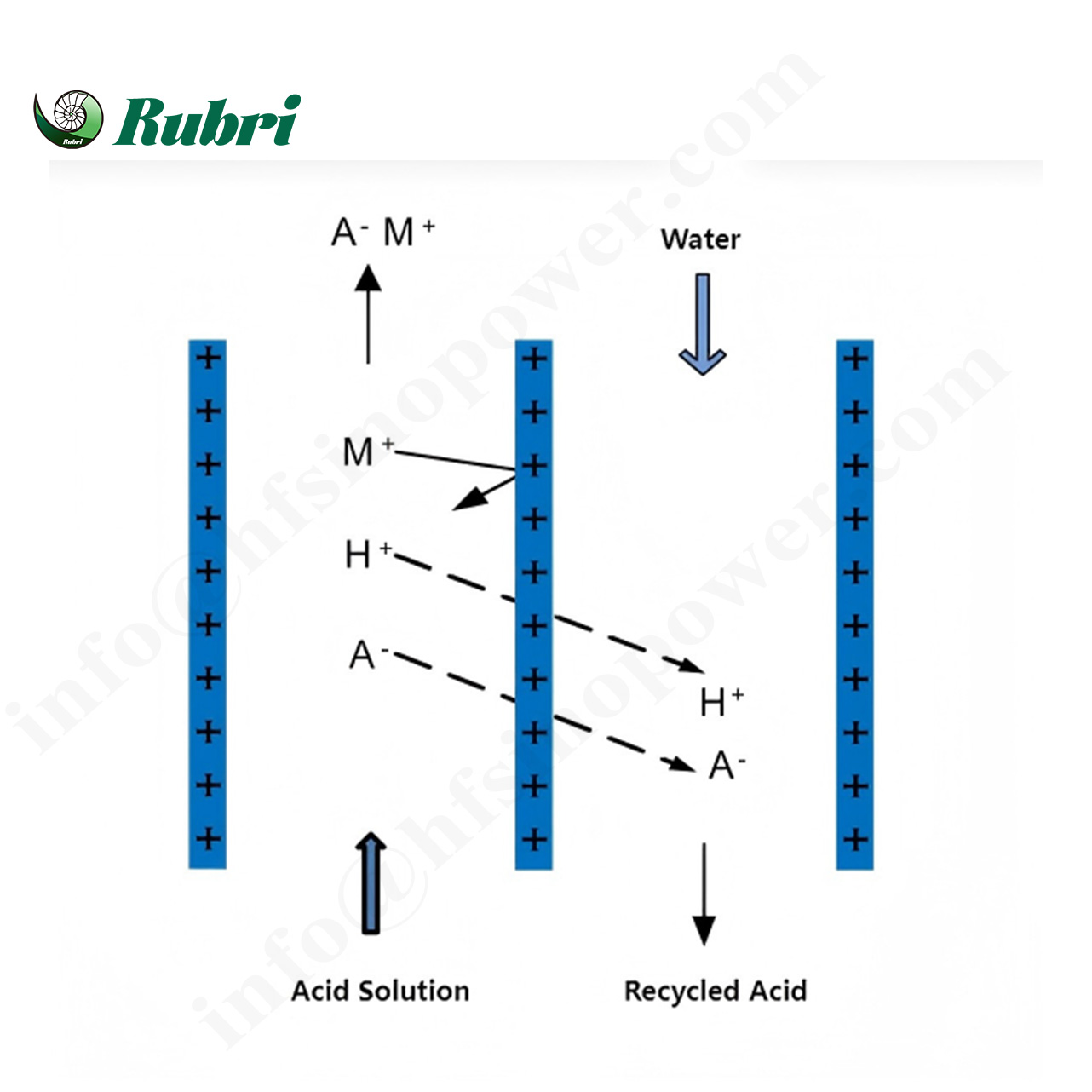

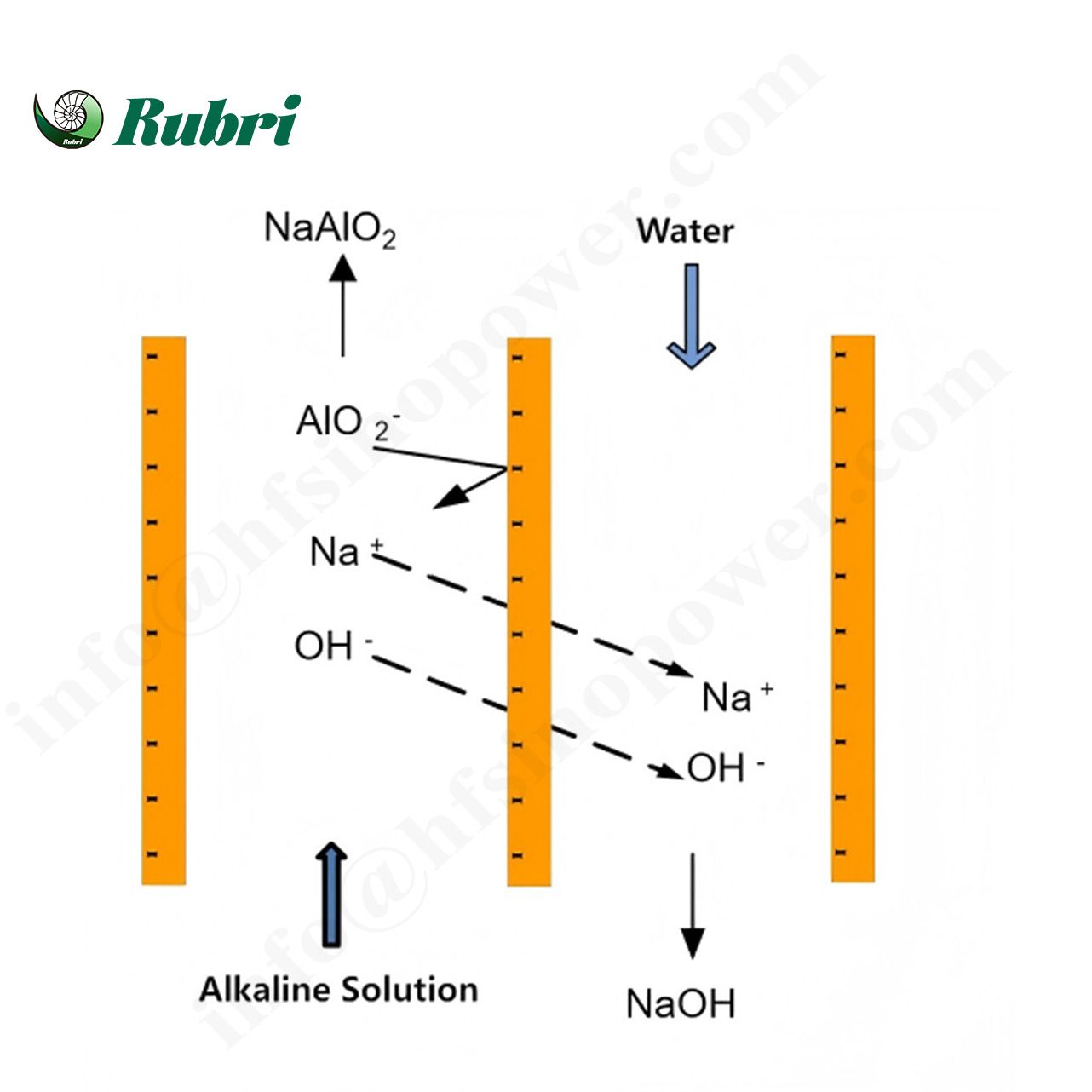

Diffusion Dialysis

Diffusion Dialysis Membranes

Including acid recovery diffusion dialysis membranes and alkali recovery diffusion dialysis membranes.

Diffusion Dialyzers

Equipment for separating alkali (acid) by arranging diffusion dialysis membranes, dialysis chamber separators, and diffusion chamber separators in a certain order, placing water distribution plates on both sides and clamping with clamping plates.

Working Principle

The diffusion dialysis process takes concentration difference as the driving force, and uses the selective permeability of (anion) cation exchange membranes to (acid) alkali and high retention of salts or other components to separate (acid) alkali from salts or other components in the solution. The separated alkali (acid) solution is reused in the production process.

Industrial Application of Diffusion Dialysis

1.Electronic Aluminum Foil Industry Waste Acid Recycling Project

2.Graphite Industry Waste Acid Recycling Project

3.Hydrometallurgy Industry Waste Acid Recycling Project

4.Steel Pickling Industry Waste Acid Recycling Project

5.Titanium Dioxide Industry Waste Acid Recycling Project

Homogeneous Membrane Electrodialysis

Homogeneous Membrane Electrodialysis

Including anion exchange membranes and cation exchange membranes.

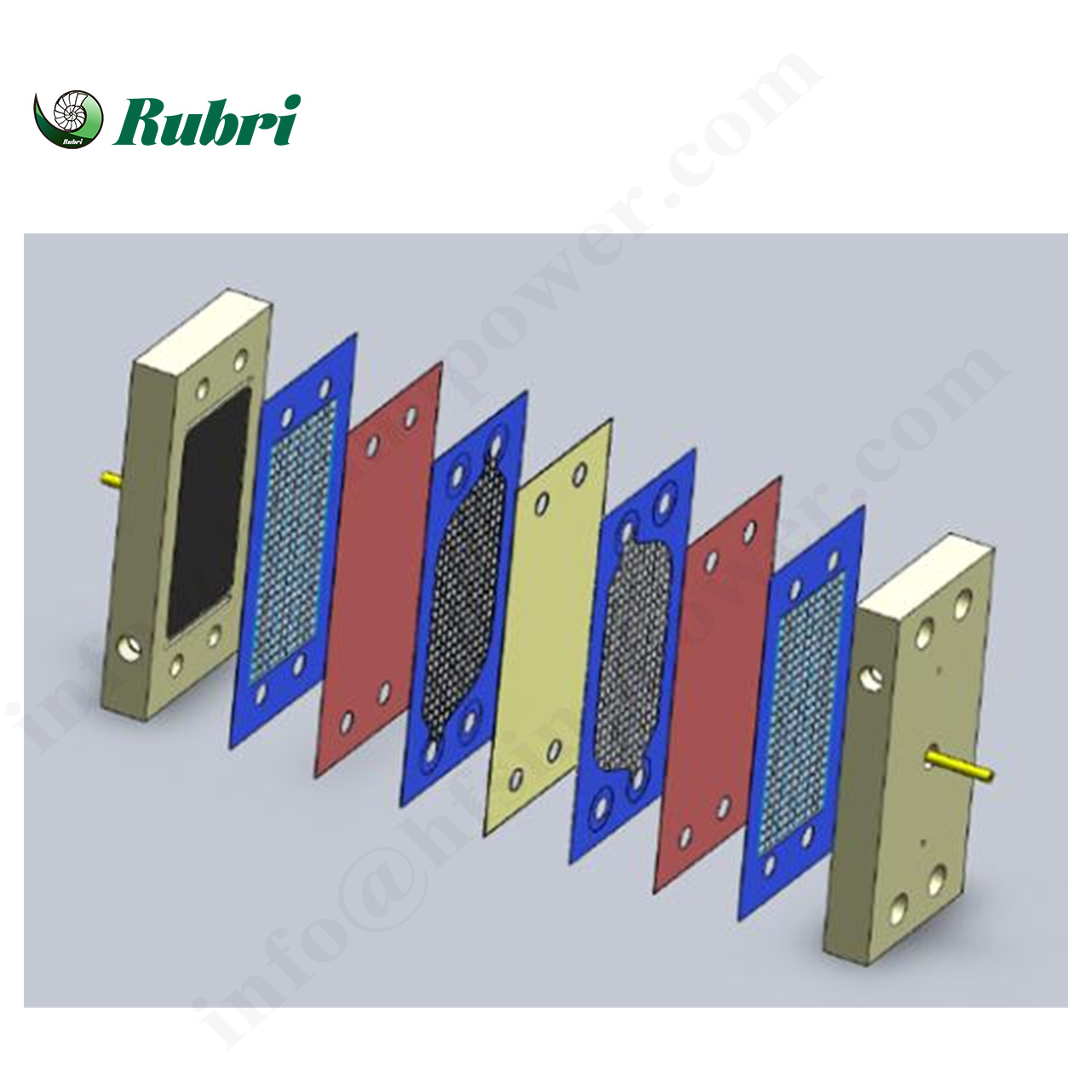

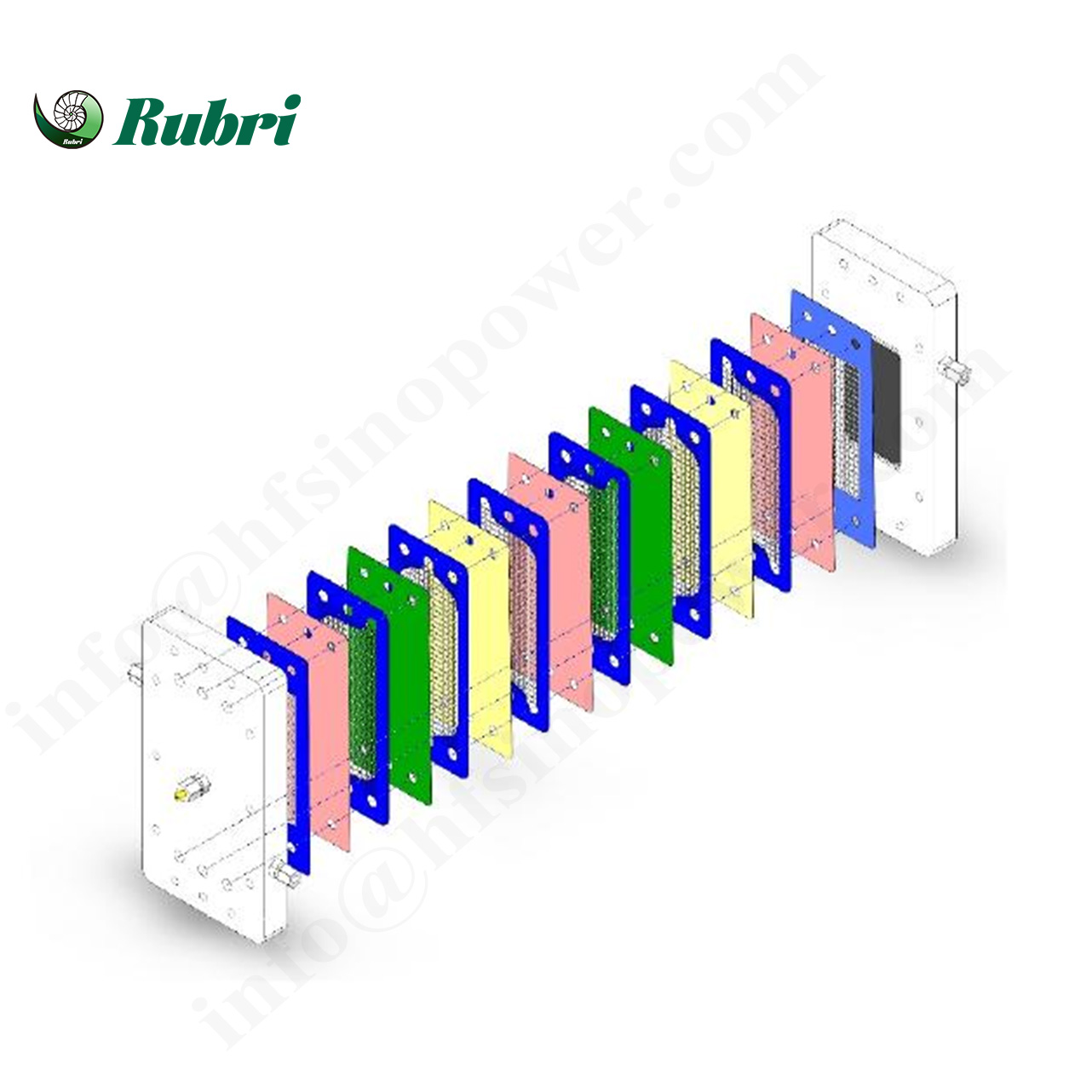

Electrodialyzers

Assembled by alternating anion membranes and cation membranes, separated by separators, and equipped with electrode plates, polar plates and end plates.

Working Principle

Directional migration of ions under the action of an electric field and selective permeability of ion exchange membranes

Application of Homogeneous Membrane Electrodialysis in Industrial Production

1.Treatment of Electroplating Wastewater

2.Concentration of Dilute Brine

3.Lithium Extraction from Salt Lake Brine

4.Acid Concentration

5.Treatment of High‑Salinity and High‑COD Wastewater

6.Alkali Recovery from Viscose Fiber and Desalination of Xylose

7.Treatment of Wastewater from Rare‑Earth Product Production

8.Material Desalination & Amino Acid Desalination

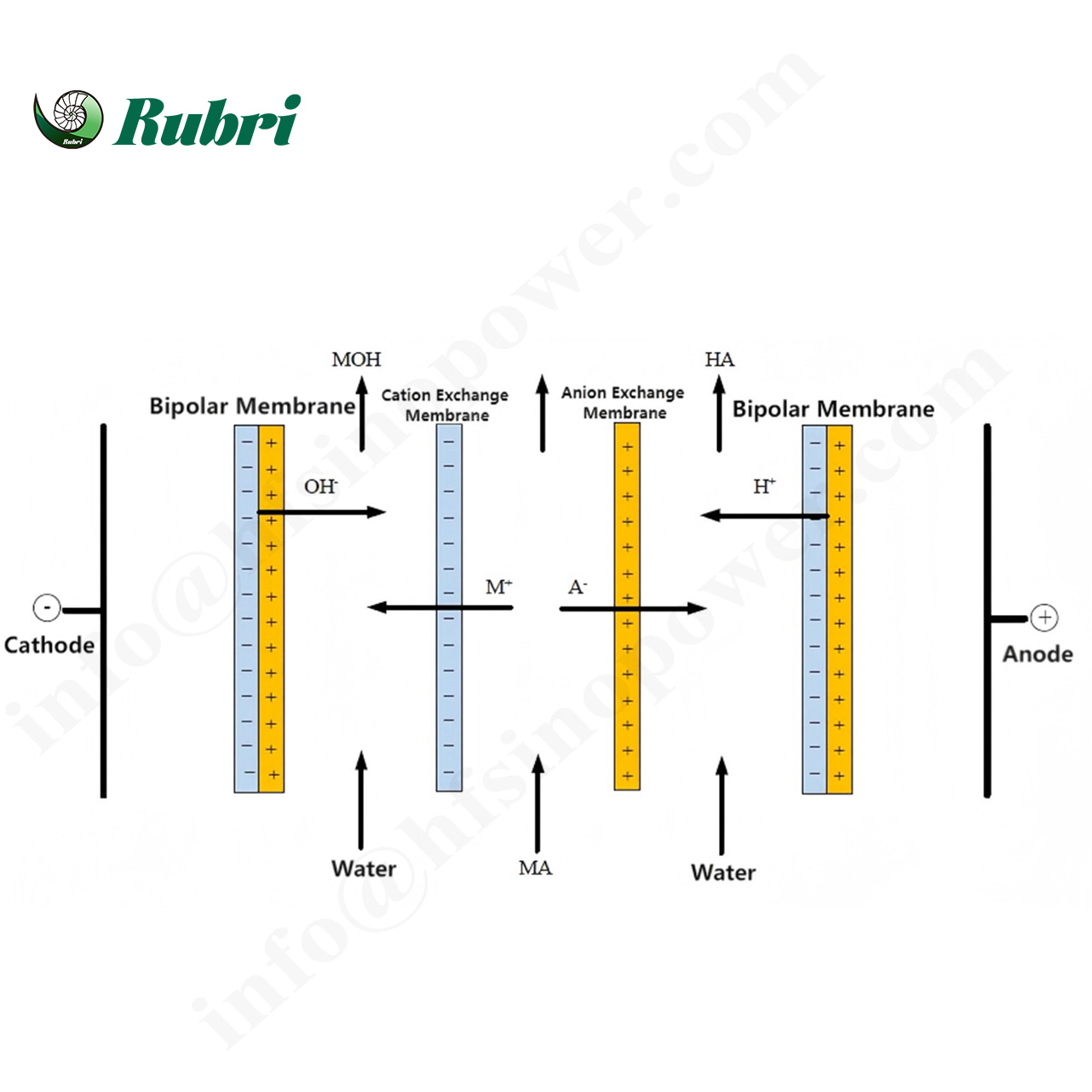

Bipolar Membrane Electrodialysis

Bipolar Membranes

Composed of a composite of anion membrane layer and cation membrane layer, which can perform electro-dissociation of water or alcohol under the drive of an electric field.

Equipment Structure

Assembled by alternating bipolar membranes, anion membranes, and cation membranes, separated by separators, and equipped with electrode plates, polar plates and end plates.

Working Principle

Water is dissociated into H⁺ and OH⁻ ions, which combine with corresponding anions and cations respectively to form acids and alkalis. At the same time, wastewater desalination and acid/alkali preparation are realized.

Industrial Application of Bipolar Membrane Electrodialysis

1.Bipolar Membrane Electrodialysis for Organic Acid/Alkali Conversion and Concentration

2.Bipolar Membrane Electrodialysis for

Resource Utilization of Brine Treatment