What Are You Looking For?

Ammonia efficiently decomposes into hydrogen and nitrogen under catalyst action; after deammoniation and purification, high‑purity hydrogen is obtained, ensuring safe production. Using green ammonia enables zero‑carbon hydrogen production. The hydrogen is pressurized, stored, and precisely dispensed to vehicles via a sequential control panel and hydrogen dispenser, delivering an efficient and safe on‑site supply solution.

Brand :

RubriCustomization :

support

What is ammonia-based hydrogen production?

We provide a one‑stop green hydrogen solution based on industrial ammonia‑to‑hydrogen equipment. Using liquid ammonia (NH₃) as feedstock, the ammonia is catalytically decomposed under energy‑saving, high‑efficiency ammonia decomposition catalysts, producing a hydrogen‑nitrogen mixture of 75 % H₂ and 25 % N₂. The mixture then passes through a purification unit to obtain high‑purity hydrogen, enabling safe and efficient hydrogen transport.

| Designed hydrogen output (kg/day) | 100-2000 | Ammonia decomposition conversion rate |

>99.5%

|

| Hydrogen production zone area(㎡) | 24-150 | Rated installed power(kW) | 80-2200 |

| Liquid ammonia consumption (kg/h) | 29.53-590.63 | Power supply |

380V/50Hz

|

Our advantages

1. Economy: Low ammonia storage & transport cost, competitive hydrogen price.

2. Convenience: Ammonia readily available, mature logistics; skid-mounted, compact, easy to operate.

3. Efficiency: Low-temp catalysis boosts efficiency & reduces energy consumption; high-purity H₂, high recovery.

4. Safety: Ammonia odor alerts; low temp, explosion-proof.

5. Intelligence: PLC precise control; remote interlock.

Deployment scenario

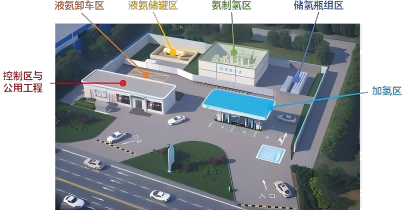

1. Integrated H₂ station: On-site production & refueling for fuel cell vehicles, urban & intercity transport.

2. Fuel cell testing: High-purity H₂ for single cells, stacks, systems; performance & durability tests.

3. Protective gas: For pharma hydrogenation, aerospace propellants, fine chemicals; prevents oxidation, boosts purity.

4. Electronics: Semiconductor wafers, chip welding, specialty gas prep, LCD panel reduction protection.