What Are You Looking For?

Flexible graphite bipolar plates are innovative fuel cell components manufactured using expanded graphite materials through specialized processes. Combining the excellent conductivity of traditional graphite with unique flexibility characteristics, they represent an innovative lightweight solution for fuel cell development.

Brand :

RubriCustomization :

YesMOQ :

100

Product Features

1.Material Properties

99% high-purity expanded graphite

Polymer binder composite modification

0.1-0.5mm bending deformation capability

2.Process Characteristics:

Roll-to-roll continuous forming process

Low-temperature curing technology (<200℃)

Capable of stamping complex flow channels

Supports ultra-thin designs

3. Competitive Advantages

Excellent vibration resistance

Superior sealing adaptability

Cost advantages for mass production

Convenient assembly processability

Parameters

| Item | Unit | Specifications |

| Thickness | mm | 0.6-1.0 |

| Bending strength | Mpa | ≥35 |

| Thickness tolerance | mm | ±0.06 |

| Resistivity | mΩ ·cm | 1.5-2.7 |

| Contact resistance | (0.4Mpa)/mΩ ·cm² | 0.6-1.0 |

| Tensile strength | Mpa | ≥30 |

| Conductivity | S/cm | <0.1 |

Multiple Usage Scenarios

Automotive fuel cell systems

Portable power devices

UAV power systems

Special mobile power supplies

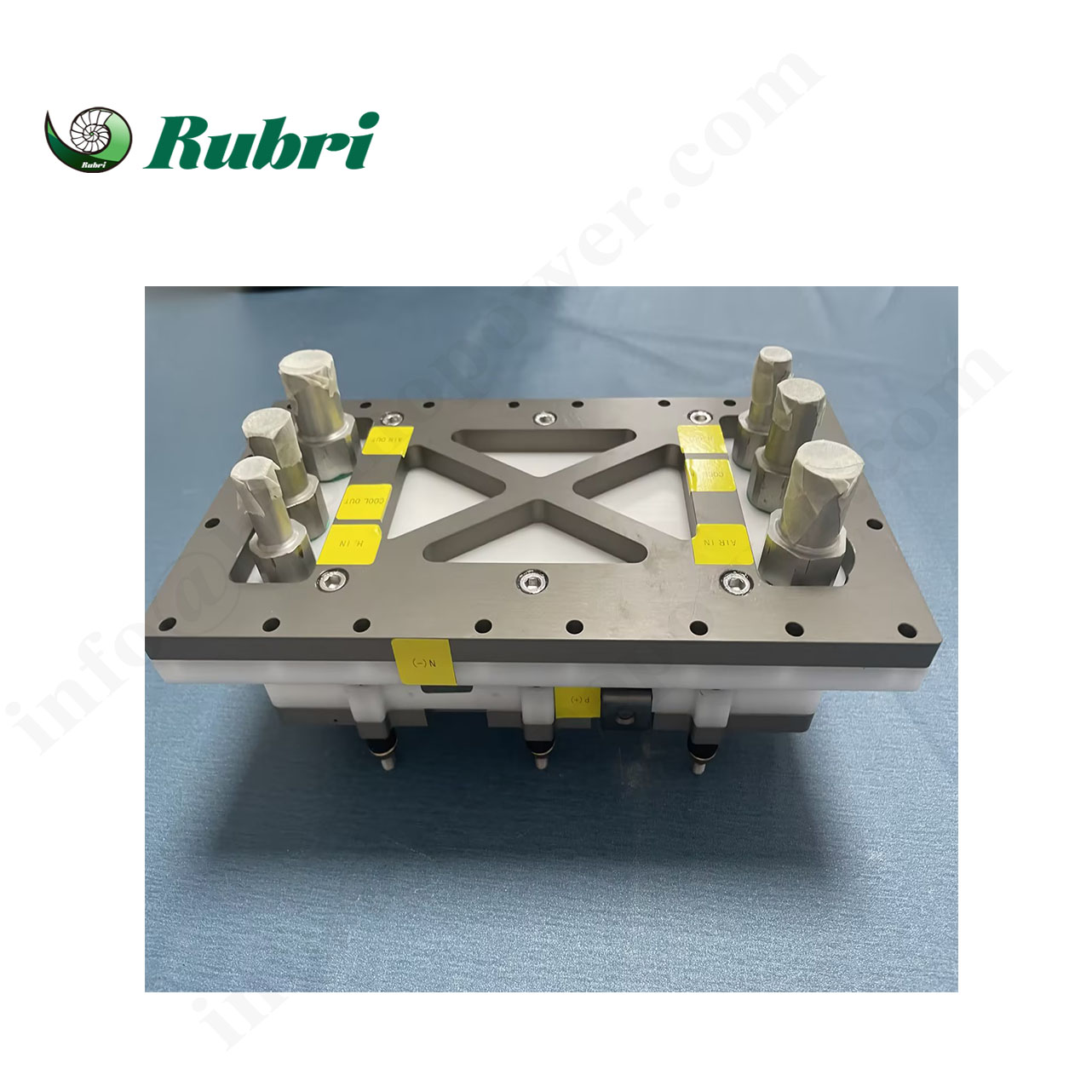

Water/liquid cooled hydrogen fuel cells can be used in larger power generation systems.Metal or graphite bipolar plate optional, DC or AC output optional, customizable for various using scenarios.

Read More

With higher cooling efficiency to quickly take away the heat generated, water/liquid cooled hydrogen fuel cells can be used in larger power generation systems.

Read More

PEM hydrogen fuel cell adopts Proton Exchange Membrane Technology to convert hydrogen and oxygen into water and electricity. A PEM fuel cell generates power without producing pollution or carbon emission.

Read More

Air cooled fuel cell adopts proton exchange membrane technology to generate power without producing pollution or carbon emission. The new energy fuel cell has a variety of application scenarios.

Read More

With simple system design, air cooling fuel cell can be used for various scenarios, such as hydrogen bicycles,hydrogen powered tricycles, sightseeing vehicles, hydrogen drones, small power unmanned ship and portable power stations etc.

Read More

PEM hydrogen fuel cell adopts Proton Exchange Membrane Technology to convert hydrogen and oxygen into water and electricity. A PEM fuel cell generates power without producing pollution or carbon emission.

Read More

With simple system design, air cooling fuel cell can be used for various scenarios, such as hydrogen forklifts, hydrogen trucks, hydrogen powered buses, hydrogen fuel cell cars, hydrogen energy boats, as well as sationary backup power supply.

Read More

PEM hydrogen fuel cell adopts Proton Exchange Membrane Technology to convert hydrogen and oxygen into water and electricity. A hydrogen fuel cell generates power without producing pollution or carbon emission.

Read More

IPv6 network supported

IPv6 network supported