What Are You Looking For?

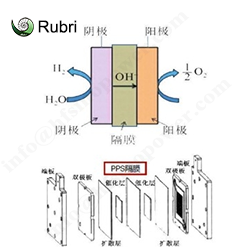

Alkaline electrolysis water hydrogen production technology dominates the field of water electrolysis hydrogen production due to its advantages such as low cost, long lifespan, and abundant material sources. The PPS membrane, made from high-performance specialty engineering plastic polyphenylene sulfide (PPS), maintains stable performance in high-temperature and alkaline environments, making it suitable for alkaline hydrogen production.

Brand :

RubriCustomization :

SupportProduct Functionality

1. Isolate cathode and anode gases to improve hydrogen purity.

2. Ensure free ion transport to enhance hydrogen production efficiency.

|

Basic Parameter |

|||

|

Inspection Items |

Testing Unit |

Inspection Specification |

Inspection Standard |

|

Dimension |

mm |

2000X2000 (Dimension customizable) |

GB/T4669-2009 |

|

Thickness |

mm |

0.85士0.10 |

JISL1096-2010 |

|

Grammage |

g/m² |

450士20 |

GB/T466902008 |

Principle of operation and application scenarios

|

Physical Properties |

|||

|

Inspection Items |

Testing Unit |

Inspection Specification |

Inspection Standard |

|

Tensile Strength |

N/5cm |

Warp>1500 |

GB/T3923.1-2013 |

|

N/5cm |

Weft>1500 |

||

|

Water Absorption Time |

S |

<10 |

GB/T21655.1-2008 |

|

Operating Temperature |

℃ |

110 |

Industry Standard |

|

Core Indicators |

|||

|

Inspection Items |

Testing Unit |

Inspection Specification |

Inspection Standard |

|

Surface Resistance |

0/cm² |

<0.25(60℃) |

SJ/T10171.5-1991 |

|

Air Tightness |

mmH₂0 |

>500 |

JC/T211-2009 |

Product Features

1.Product test conditions: mass fraction 30% KOH solution, operating temperature 60 °C

2.Excellent heat resistance, mechanical strength, and electrical properties

3. Two key indicators for measuring performance: air tightness and surface resistance